Introduction to Control Cables & Overview

| CSS Drop Down Menu by PureCSSMenu.com | < Previous Page|Next Page > |

207

®

SeaStar Solutions offers several models of universal

3300/33C type cables, each suited to certain operating

conditions and installation parameters. Below are key

variables that affect how cables perform:

Backlash: the lost motion between the amount of

movement put in (input end of the cable) and the

amount of movement which occurs at the output

end of the cable. Some motion is generally lost in

“take up” between the inner wire (core) of the cable

and the outer casing (conduit). Backlash manifests

itself as free play (slop) felt at the control handle.

Efficiency: the percentage of input force that is

transmitted through the cable as output force.

For example, if a 10-pound force was exerted on

the cable at its input end and resulted in the cable

exerting an 8-pound output force, the cable would

be 80% efficient.

Breakaway: the “feel” of the cable when put into

motion; the breakaway threshold is the force that

must be applied to the cable’s input end before

something happens at the output end. An example of

excessive breakaway: a control that would have to be

moved to half-throttle before the engine responded.

The control cable is a very important component in

the control system. It is the vital link between the

control head and the propulsion unit. Employing the

best cable helps insure that your shift and throttle

system operates smoothly and efficiently. The design,

technology and materials, which are used in SeaStar

Solutions cables, have literally set the standard for the

entire marine industry.

Our control cables are environmentally tested

for marine applications. They have stainless steel

terminals and conduit fittings, as well as stainless or

nylon covered core wires with moisture protective

seals for added corrosion protection and longer life.

Their durable HDPE outer jackets resist abrasion and

withstand the effects of UV, salt water, chemicals,

gasoline and oil. Each SeaStar Solutions cable is

lifetime lubricated at the factory.

SeaStar Solutions

pioneered the development of high

efficiency control cables. Since not all cables utilize

this technology there can be significant operating

differences between SeaStar Solutions cables and

other brands.

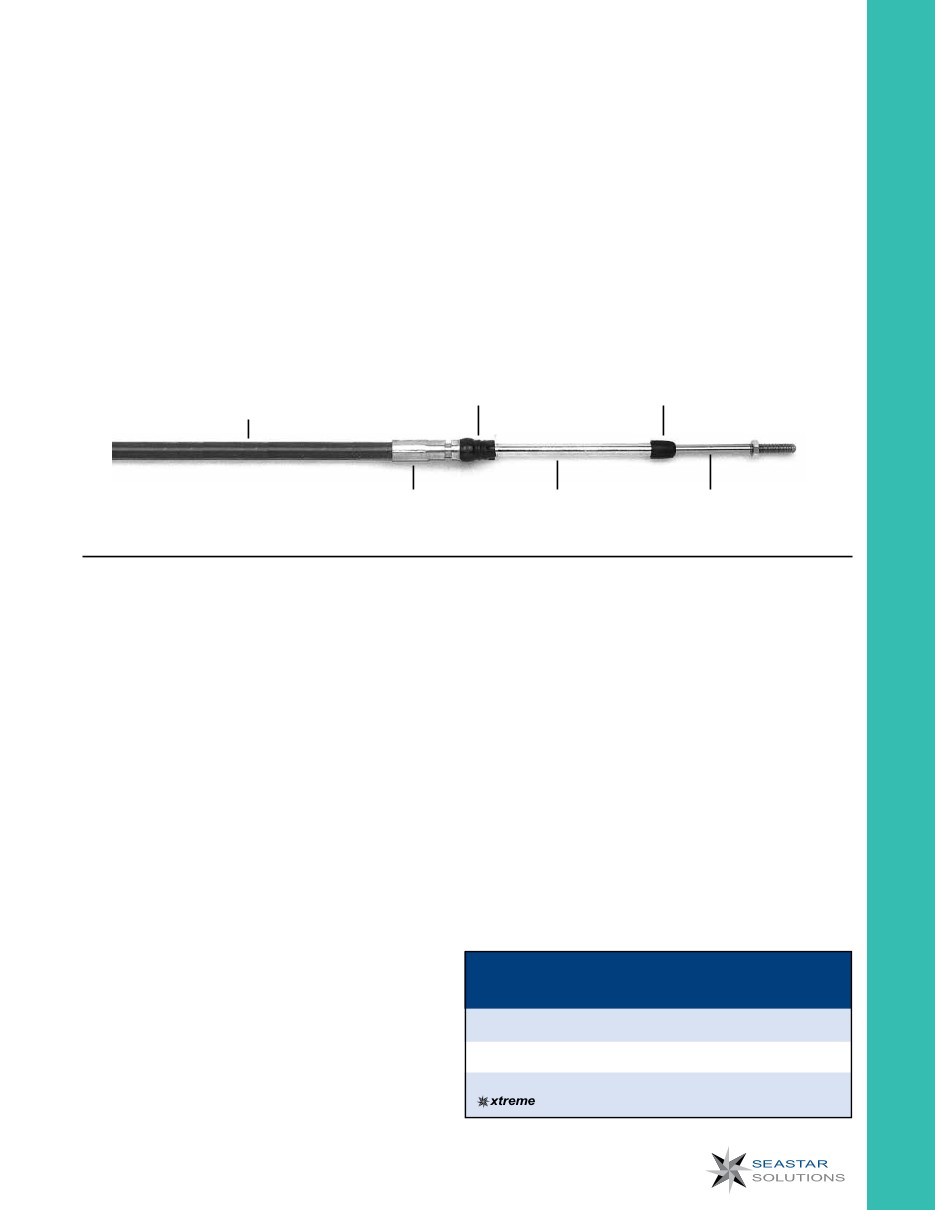

Corrosion resistant

stainless steel terminal

Protective wiper seal

Protective swivel seal

Corrosion-resistant nickel

plated brass swivel tube

Corrosion resistant stainless

steel conduit fitting

Ultraviolet stabilized high density

polyethylene outer jacket

3300/33C

BREAK-

LONG/

CABLE

BACK-

AWAY/

COMPLEX

HARSH

TYPE

LASH

EFFICIENCY

ROUTINGS ENVIRONMENT

CC230

Good

Good

N/A

Good

Standard

CC332

Better

Better

Better

Better

Mid-Range

CCX633

Superior

Superior

Superior

Superior

Cable Routing: the shorter and straighter the cable

routing, the better the cable will perform. With

increased length and bends, cable efficiency is

reduced, while breakaway and backlash rise.

Environment: generally, the more rugged the cable

construction, the longer the cable will last. In harsh

environments such as heavy salt and UV exposure,

control cables with thicker conduits and stainless

steel fittings will generally outlast those with thinner

conduits and brass or steel fittings.

Cable design, manufacturing tolerances, length and

installation care are additional factors to consider.

SHIFT AND THROTTLE CONTROL CABLES

HOW TO CHOOSE THE RIGHT 3300/33C CABLE:

CONTROL CABLES